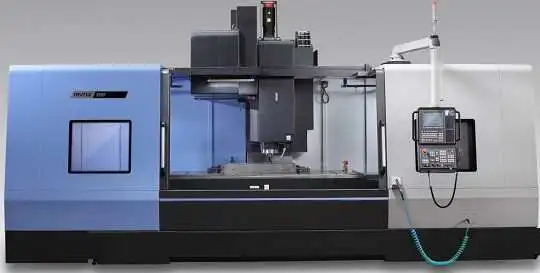

The Mynx 9500 Vertical Machining Center is designed for heavy duty cutting, high

accuracy and superior surface finishes. Featuring an arch shaped column

structure and large, box type guideways, the Mynx 9500 provides unrivaled rigidity

and unsurpassed performance for heavy duty machining. With its 50 taper

spindle, driven by a two-step gearbox, the Mynx 9500 delivers exceptionally high

torque and covers the broadest possible spectrum of tough machining

applications.

We use cookies to improve your experience. Privacy Policy.