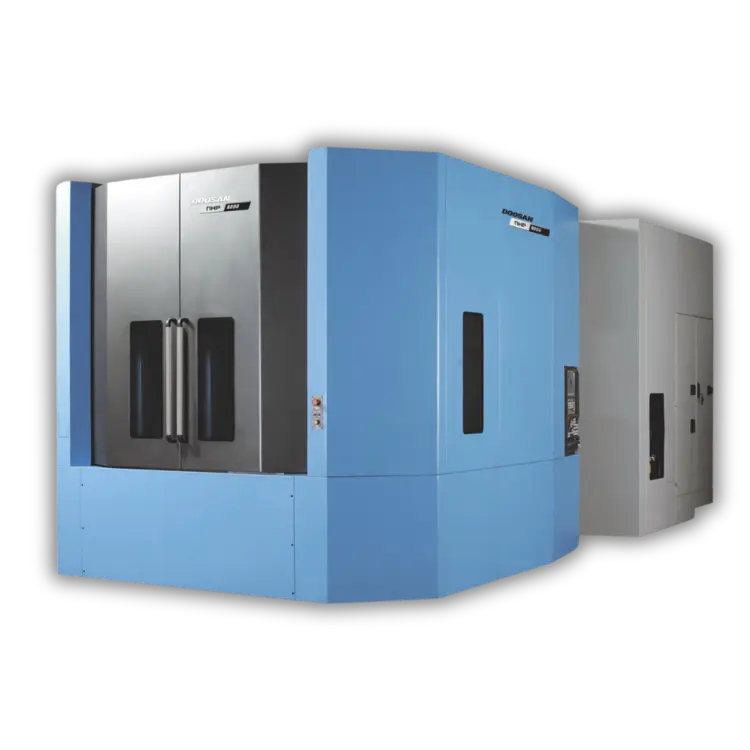

The NHP 8000 is designed for a combination of heavy duty cutting and high speed machining along with high precision over a wide range of applications. It has a powerful built-in spindle motor with a dual wound, "virtual gearbox" design, which generates high torque at low rpm for heavy chipload roughing cuts. Featuring a 50 taper tool shank, the NHP 8000 offers best in class specifications for tool diameter, length and weight and can handle the most difficult tooling scenarios. Also incorporating many advanced technological features such as FEM optimized construction, Linear Roller Motion Guides and a servo driven rotary pallet changer, the NHP 8000 is capable of remarkable performance with long term reliability. With a wide variety of factory installed options including Multi Pallet changers, large tool magazines and hydraulic fixture units, the NHP 8000 can be tailored to meet even the most demanding manufacturing challenges.

We use cookies to improve your experience. Privacy Policy.